samaresh@samarh2cryo.com

Specialized Engineering

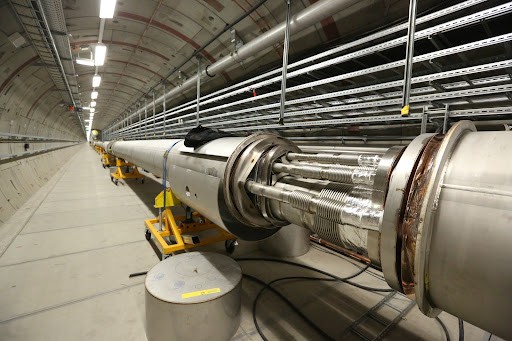

Hydrogen, Cryogenic, LNG & Energy Infrastructure

Samar H2-Cryo Services is a newly established MSME-registered engineering

services company, formed to deliver high-quality,

analysis-driven and code-compliant engineering solutions.

We support hydrogen, cryogenic, LNG, energy and process industry projects

by providing validated engineering designs, detailed analysis,

and documentation aligned with international standards.

Our engineering philosophy is built on deep technical analysis,

safety-first design and practical execution support.

EPC

EPC

Supporting EPCs, OEMs, Consultants, Fabricators & Project Owners

MSME

Government of India Registered

Multi-Disciplinary

Process • Mechanical • Piping

Code-Compliant

ASME • NFPA • ASME B31

Agile Execution

Startup Speed + Expert Discipline

Engineering Excellence Driven by Analysis, Safety & Compliance

Samar H2-Cryo Services is an engineering services company registered

under the MSME Act, Government of India, established to support

industrial, energy and infrastructure projects with technically

validated engineering solutions.

Our organization is built on the belief that strong engineering begins

with detailed analysis. We focus on technical accuracy, regulatory

compliance and practical design solutions that help our clients

enhance plant safety, operational reliability and lifecycle efficiency.

Although newly registered, our engineering team brings years of

professional experience across hydrogen, cryogenic systems, LNG,

pressure vessels, piping systems and industrial infrastructure.

We combine startup agility with the discipline and responsibility

expected from an experienced engineering organization.

- Hydrogen & Alternative Fuel Projects

- Cryogenic Storage & Transportation

- LNG / LCNG / RLNG Facilities

- Pressure Vessel & Equipment Design

- Piping & Pipe Stress Analysis

- FEA, CFD & Structural Validation

Engineering-Focused

Designs backed by calculation & simulation

Industries We Serve

Delivering engineering solutions across energy, process and industrial sectors

- Renewable Energy

- Green Hydrogen

- Alternative Fuels

- Ammonia Storage

- Hydrogen Refuelling Stations

- LNG / LCNG Stations

- RLNG & Gas Bottling Plants

- Cryogenic Storage Systems

- Cryogenic Transportation

- Carbon Capture & LCO₂

- Oil & Gas

- Process Industry

- Food & Pharmaceutical

- Agriculture & Textile

- Research & Development

What We Do

Comprehensive engineering, analysis and design services across hydrogen, cryogenic and energy projects

Hydrogen & LNG Facility Engineering

Process Flow Diagrams, mass & energy balance, plant layout, P&ID, hazardous area classification, fire-fighting layouts as per NFPA, equipment sizing, utilities and instrumentation logic.

Cryogenic Vessels & Transport Systems

Design of cryogenic vessels, ISO containers, cryogenic tankers, LNG fuel tanks, including mechanical, thermal, safety and fabrication documentation.

FEA, CFD & Pipe Stress Analysis

ASME Section VIII FEA, stress linearization, fatigue checks, CFD flow and thermal analysis, pipe stress analysis as per ASME B31.

Structural & STAAD Pro Analysis

Structural modelling, wind & seismic load analysis, equipment support design, structural optimization and detailed engineering documentation.

Finite Element Analysis (FEA)

Code-compliant design verification and advanced stress analysis for pressure vessels and cryogenic equipment

We provide detailed and code-compliant finite element analysis (FEA)

for pressure vessels, cryogenic equipment and structural components

in accordance with ASME Section VIII and other applicable

international standards.

Our FEA approach is focused on identifying critical stress regions,

validating analytical calculations and ensuring safe operation

under all governing load cases.

- Thickness verification and optimization

- Nozzle and reinforcement stress analysis

- Support, saddle and skirt stress evaluation

- Wind and seismic load assessment

- Local stress checks and stress linearization

- Fatigue and cyclic loading assessment

- 3D finite element modeling and reporting

Computational Fluid Dynamics (CFD)

Engineering simulation for flow, thermal and performance validation

Our CFD analysis services help clients understand real operating behaviour of fluids and thermal systems before fabrication and commissioning. CFD is extensively used to improve safety, performance and efficiency of cryogenic systems, pipelines, heat exchangers and process equipment.

- Velocity, pressure and temperature contour analysis

- Flow distribution and maldistribution studies

- Thermal performance evaluation

- Heat exchanger and cryogenic system analysis

- Pressure loss and turbulence modelling

- Equipment performance prediction

- Parametric studies and design optimization

Piping Engineering & Pipe Stress Analysis

Safe, flexible and code-compliant piping system design

We provide complete piping engineering support including piping isometric preparation and detailed pipe stress analysis to ensure system integrity under operating, thermal and occasional load conditions.

- Piping isometric drawings and spool details

- Pipe sizing and pressure drop calculations

- Thermal expansion and flexibility analysis

- Sustained, thermal and occasional load cases

- Nozzle load evaluation as per equipment limits

- Support and spring hanger selection

- Wind and seismic load analysis

- Stress compliance as per ASME B31 codes

Why Samar H2-Cryo Services

Clients choose Samar H2-Cryo Services for our technical depth, analytical approach and commitment to engineering accuracy.

- Strong focus on engineering calculations and validation

- Designs aligned with international codes and standards

- Multi-disciplinary engineering capability

- Clear, auditable and client-ready documentation

- Startup agility with experienced engineering discipline

- Dedicated technical support during project execution

Looking for Reliable Engineering Validation & Design Support?

Whether you are an EPC contractor, OEM, consultant, fabricator or project owner, Samar H2-Cryo Services provides engineering solutions you can trust — backed by analysis, compliance and experience.

Connect With Our Engineering TeamContact Samar H2-Cryo Services

Share your project requirements and receive technically sound engineering support

Office Address

Flat No-302, TSR Infra Developers,

Koppuravuru, Amaravati,

Guntur, Andhra Pradesh – 522508, India

Phone

+91 87093 40291

Working Hours

Monday – Saturday

9:00 AM – 6:00 PM (IST)

Engineering Enquiry

Please share brief project details. Our engineering team will review and respond with technical inputs.

Frequently Asked Questions

Common questions from EPCs, OEMs and project owners

Do you work with EPC contractors and OEMs?

Yes. We regularly support EPC contractors, OEMs, engineering consultants, fabricators and project owners with design validation, analysis and detailed engineering.

Which codes and standards do you follow?

Our engineering work is aligned with ASME Section VIII, ASME B31 piping codes, NFPA, and other applicable international and client-specific standards.

Do you provide calculation reports and drawings?

Yes. We deliver complete calculation packages, design reports, drawings and client-ready documentation suitable for review, approval and audits.

Can you support projects during execution?

We provide engineering support during fabrication, installation and commissioning phases to ensure design intent and safety compliance.

Do you take up international projects?

Yes. We support both domestic and international projects through remote engineering collaboration and digital documentation delivery.

Ready to Move Forward with Confidence?

Let Samar H2-Cryo Services support your project with engineering solutions built on analysis, compliance and professional integrity.

Start Your Engineering Discussion